|

|

Vol.

32 No. 4

July-August 2010

| The Project Place |

| |

Information about new, current, and complete IUPAC projects and related initiatives.

See also www.iupac.org/projects |

Structure, Processing, and Performance of Ultra-High Molecular Weight Polyethylene

|

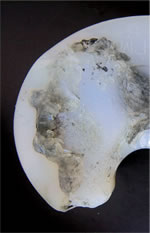

Delaminated UHMWPE knee component after revision

surgery due to pain and

instability (E. Gomez-Barrena et al. Acta Orthopaedica 2008, 79(6), 832-840; doi:10.1080/

17453670810016939). |

Compression moldings made from ultra-high molecular weight polyethylene (UHMWPE), are widely used in hip and knee replacements, where they generally perform well over many years. However, in a few cases, service lifetimes are drastically shortened by microcracking and wear. The aim of the present project is to develop improved quality-assurance procedures that can overcome this problem. There are major challenges in characterizing products based on PE with Mw > 1 MDa: conventional solution-based methods cannot be used to measure molecular weight distributions, and melt viscosities are so high that reactor powder is consolidated by sintering at elevated temperatures, so that tensile strength depends critically on the extent to which polymer chains have diffused across interfaces and formed entanglements. The outcome varies with processing temperature, pressure, and time.

Clive Bucknall will lead a task group comprising 21 academic and industrial researchers from America, China, Korea, and 5 European countries, which will study three grades of HMWPE, having

Mw ≈ 0.4, 5 and 9 MDa, and develop methods for observing and quantifying the changes that occur during processing. The emphasis will be on changes that could affect fracture and wear resistance, which will also be measured.

For more information, contact Task Group Chair Clive B. Bucknall <[email protected]>.

www.iupac.org/web/ins/2010-019-1-400

Page

last modified 30 June 2010.

Copyright © 2003-2010 International Union of Pure and Applied Chemistry.

Questions regarding the website, please contact [email protected] |