Vol.

26 No. 3

May-June 2004

Rheological and Mechanical Properties of Poly (α-Methylstyrene-co-acrylonitrile)/Poly (Methylacrylate-co-methyl methacrylate) Blends in Miscible and Phase-Separated Regimes of Various Morphologies. Part IV. Influence of the Morphology on the Mechanical Properties (IUPAC Technical Report)

by V. Altstädt, L. De Lucca Freitas, and D.W.Schubert

Pure and Applied Chemistry

Vol. 76, No. 2, pp. 389–413 (2004)

|

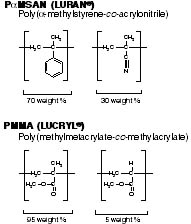

| Chemical structures of PαMSAN and PMMA. |

|

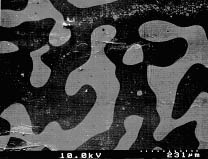

| Scanning electron micrograph of the annealed PαMSAN/PMMA 40/60 blend. Crack propagation velocity: 10-5 mm/cycle. (Magnification: 130x) |

Influences of the morphology on the thermal and mechanical properties of poly (α-methylstyrene-co-acrylonitrile)/poly(methylacrylate-co-methyl methacrylate) (PαMSAN/PMMA) blends have been investigated. Differential scanning calorimetry (DSC) measurements confirmed that all blends were phase separated due to the temperature at which they were extruded and squeeze molded. Based on the cloud points of 17 blends and transmission electron microscopy (TEM) micrographs, the interaction parameters as a function of temperature and composition were calculated for the lower critical solution temperature (LCST) system. The morphology of the system was varied by annealing without changing its composition, but no clear conclusions on the influence of morphology on fracture toughness could be. In situ strained thin sections in the TEM indicated no effect of annealing on the micromechanical behavior. Shear deformation was observed as the prevailing deformation mechanism in the PαMSAN and fibrillized crazing in the PMMA-rich blends. From the features of the fracture surface investigated by scanning electron microscopy (SEM), the conclusion can be drawn that the fatigue crack propagates faster in the more brittle PαMSAN phase, but the overall advance of the crack front is controlled at the interphases, resulting in a crack propagation gradient along the interphase.

www.iupac.org/publications/pac/2004/7602/7602x0389.html

Page

last modified 18 May 2004.

Copyright © 2003-2004 International Union of Pure and

Applied Chemistry.

Questions regarding the website, please contact [email protected]

|