|

|

Vol.

28 No. 2

March-April 2006

Microstructure

and Properties of Thermotropic Liquid-Crystalline Polymer

Blends and Composites

Liquid-crystalline

polymers (LCPs), comprised of rigid (or semi rigid) rod-like

molecules, are usually classified into two groups: lyotropic

LCPs and thermotropic LCPs, based on the conditions for the

formation of their liquid-crystalline state.

Lyotropic LCPs, such as poly(ρ-phenylene terephthalamide)

(PPTA) are processed to high-strength, high-modulus fibers

by the solution-spinning technique. Thermotropic LCPs (TLCPs)

are processed and molded to structural parts of different

shapes by means of conventional processing for thermoplastics,

such as extrusion and injection molding.

The synthesis and modification of TLCPs for different final

applications are hot topics for industrial and academic research.

The copolymerization of different comonomers produces copolymers

classified into different series, (e.g. Rodrun, Vectra, and

Xydar) with different liquid crystalline characteristics,

melting temperatures, and rheological behavior. These series

find their different end-use applications by injection molding,

extrusion, stretching, blowing, and spinning.

In recent years, the rapid development of information technology

products has lead to an annual consumption growth of 25% for

commercialized TLCP blends and composites. To fabricate final

products, different commercialized grades of TLCP blends and

composites are available as glass-fiber or carbonfiber-reinforced,

glass-bead, glass-flake, or silica-filled grades. The microstructure

of commercialized TLCP blends and composites is closely related

to their processing conditions. The relation between the rheological

properties and the resultant microstructure of these blends

and composites should be well established. The aim of this

project is to evaluate the microstructure–property relation

of the commercialized TLCP blends and composites by rheological

measurement, morphological observation, and evaluation of

property.

|

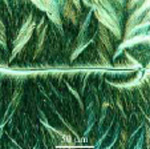

Inversion

wall revealed by spontaneous band texture

in a liquid crystalline polymer; rigid copolyester of

hydroxybenzoate (HBA) and hydroxynapthoate (HNA)

(1:1); Cross-polarized light microscopy.

(Source: Dr W

Song, Department of Materials Science and Metallurgy,

University of Cambridge; www.doitpoms.ac.uk) |

Recently,

another report has been published in Pure

and Applied Chemistry 76,

2027–2049 (2004): “Rheological Properties

and Associated Structural Characteristics of Some Aromatic

Polycondensates, Including Liquid-Crystalline Polyesters and

Cellulose Derivatives,” by J.L. White, L. Dong, P. Han,

and H.M. Laun. This paper reports four different types of

liquid crystalline polyesters and one type of glass, fiberfilled

LCP, with sections as polarized light microscopy, capillary

rheometry (bagley plots and correction vs. wall-shear stress),

extrudate swell, structural studies of extrudates, and oscillatory

shear measurements (amplitude sweeps, time sweeps, frequency

sweeps, and temperature sweeps).

This project will focus on TLCP blends and composites. The

topics of study include:

1.

rheological measurements of TLCP blends and composites

2. dynamic viscoelasticity, stress relaxation, and shear/elongational

viscosities

3. morphological observation of molded samples

4. scanning electron microscopy, transmission electron microscopy,

and atomic-force microscopy observation

5. blending with other polymers

6. rheological properties of blends and microstructure observation

7. crystallization of TLCP blends and composites

8. differential scanning calorimetry measurements, scanning

electron microscopy, and polarized optical microscopy observation

9. mechanical testing of molded samples

10. static mechanical properties and dynamic mechanical

analysis

For more information

and comments, contact the task group chairman, Jiasong He

<[email protected]>.

www.iupac.org/projects/2004/2004-044-2-400.html

Page

last modified 10 August 2006.

Copyright © 2003-2006 International Union of Pure and

Applied Chemistry.

Questions regarding the website, please contact [email protected]

|